SEDAL has been involved for the last years in the optimization of Water-Based Tape Casting Process to produce high-quality ceramic substrates for electronic applications

Sedal Ceramics is the Technical Ceramics division of Sedal GROUP, a leading company based in Barcelona and worldwide supplier of ceramic cartridges. The company is focused on the design, manufacture, and sale of ceramic components for electronics, energy and automotive, as well as for industrial engineering and sanitary sector. Sedal has a fully integrated process from the preparation of the raw material to the production of the final components.

Water-Based Tape Casting Process

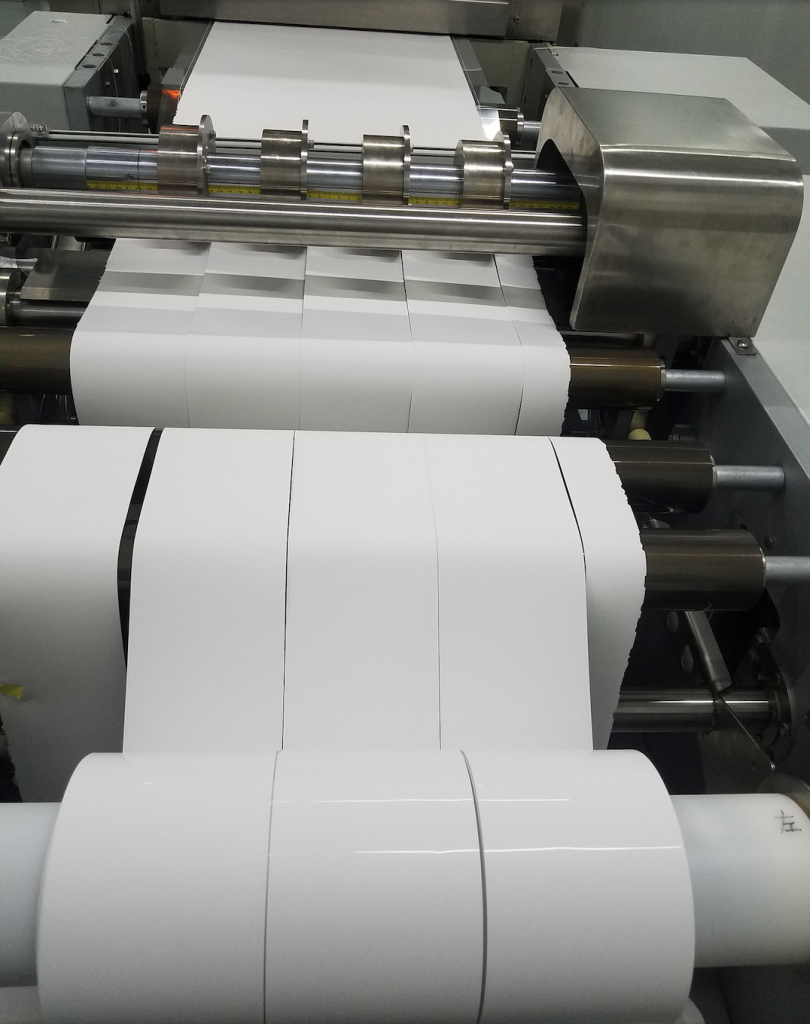

Towards our commitment to the environment by introducing of a cleaner processes within our mass production, Sedal has been involved for the last years in the optimization of the water-based tape casting process to produce high quality ceramic substrates for electronic applications. It is well known that water-based tape casting is a low-cost and especially an environmentally friendly process. But its main difficulty relies on the drying conditions and controlling the thickness of the tapes obtained, among others. That is why, its mass production introduction is being a difficult task for the ceramic substrate´s industry and is the main reason for which the organic solvent based tape casting process predominates, even its complex installations, high cost and harmful effect for the environment.

High quality ceramic substrates

Despite this, in SEDAL we have optimized the water-based process for different thicknesses of alumina 96 substrates for mass production: from 0,3mm to 1mm. Slurry formulation, tape casting process conditions, densification and post sintering processes, all have influence on the final quality of the substrate, but also are conditioning the continuity of the process. On the other hand, using the optimized process, in Sedal we can produce high quality ceramic substrates that accomplish state of the art standards required by electronic applications.

In addition, physical, mechanical, electrical, thermal and surface properties are showing that this process can be used industrially in continuous production. That means gaining a cleaner process without losing performance of the substrates. Some results of our ceramic substrates obtained in the mass production by water-based tape casting process are shown in the editorial article published at Ceramic Applications Magazine entitled Water-Based Tape Casting Process to Produce High-Quality Ceramic Substrates.

If you would like to have more information about ceramics substrates, cartridges or electronic mixing water systems and talk with our Sales or Technical Department, do not hesitate to contact us at sales@sedal.com. Our team is always happy to help you.